Combustion chamber

The "Scots" that wis uised in this airticle wis written bi a body that haesna a guid grip on the leid. Please mak this airticle mair better gin ye can. |

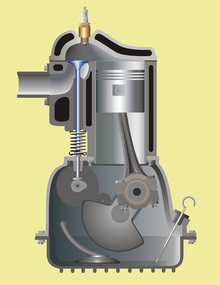

A combustion chamber is that pairt o an internal combustion ingine (ICE) in which the fuel/air mix is burned. ICEs teepically comprise reciprocating piston ingines, rotary ingines, gas turbines an jet turbines.

Internal combustion ingine

[eedit | eedit soorce]The combustion process increases the internal energy o a gas, which translates intae an increase in temperature, pressure, or volume dependin on the configuration. In an enclosure, for ensaumple the cylinder o a reciprocating ingine, the volume is controlled an the combustion creates an increase in pressure. In a continuous flow seestem, for ensaumple a jet ingine combustor, the pressure is controlled an the combustion creates an increase in volume. This increase in pressure or volume can be uised tae dae work, for ensaumple, tae muive a piston on a crankshaft or a turbine disc in a gas turbine. If the gas velocity changes, thrust is produced, sic as in the nozzle o a rocket ingine.

Petrol ingine

[eedit | eedit soorce]At tap dead centre the pistons o a petrol ingine are flush (or nearly flush) wi the tap o the cylinder block. The combustion chamber mey be a recess aither in the cylinder heid, or in the tap o the piston. A design wi the combustion chamber in the piston is cried a Heron heid, whaur the heid is machined flat but the pistons are dished. The Heron heid haes proved even mair thermodynamically efficient than the hemispherical heid.[citation needit] Intake valves permit the inflow o a fuel air mix; an exhaust valves allou burnt gases tae be scavenged.

Various shapes o combustion chamber hae been uised, sic as: L-heid (or flathead) for side-valve ingines; "bathtub", "hemispherical", an "wedge" for owerheid valve engines; an "pent-roof" for engines haein 3, 4 or 5 valves per cylinder. The shape o the chamber haes a merked effect on power output, efficiency an emissions. The designer's objectives are tae burn aw o the mixture as completely as possible, while avoiding excessive temperatures which creaut nitrogen dioxide. This is best achieved wi a compact rather than elangatit chamber.